The GLAMAtronic development department accompanies

our customers with any questions for CD-welding.

Our trained team supports by:

The design of the components to be welded and its weld preparation

The determination of optimal weld parameters

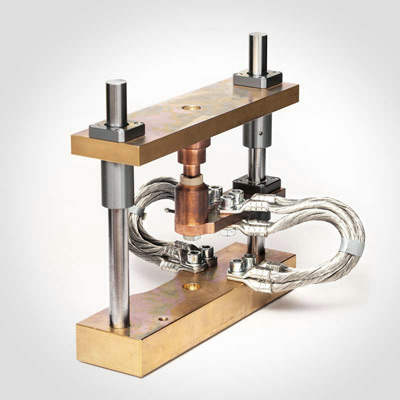

The production of welding tools and trial gauges

The manufacture and design of new welding tools and welding equipment

The metallographic and mechanical material tests of the welded components and their subsequent interpretation and advice

Production of sample parts or small series

Equipment

In order to perform welding tests, our development department can use 5 CD-welding machines in C-frame and Portal-frame construction from 4 kJ and 10 kN up to 130 kJ and 200 kN, and 1 MF welding machine with 130 kVA and 10 kN.

The tooling required for the welding test (for simple to very complex welding applications) are built in close cooperation and coordination with our customers.

Investigation

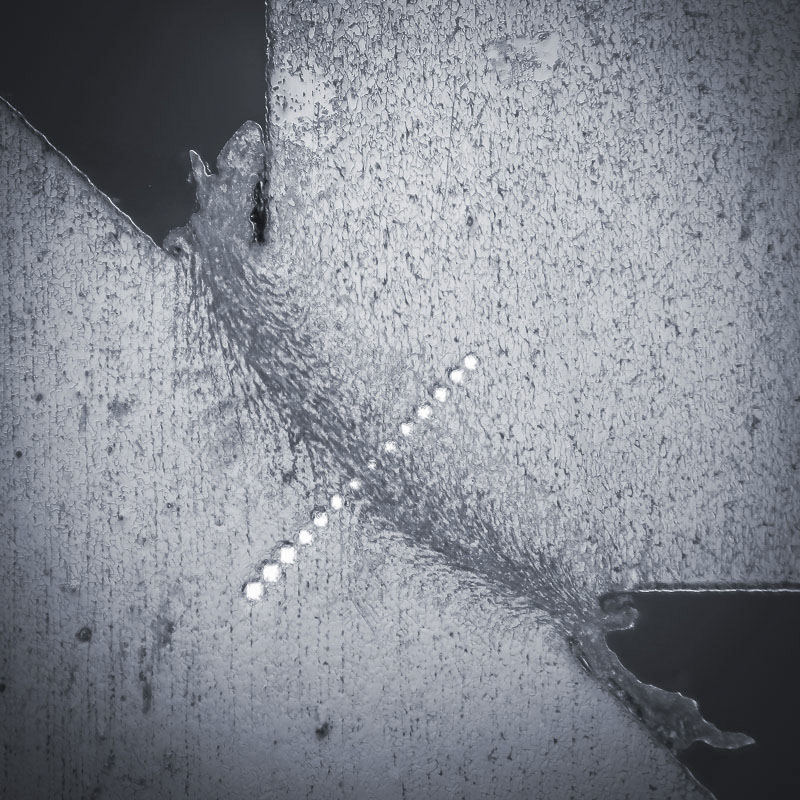

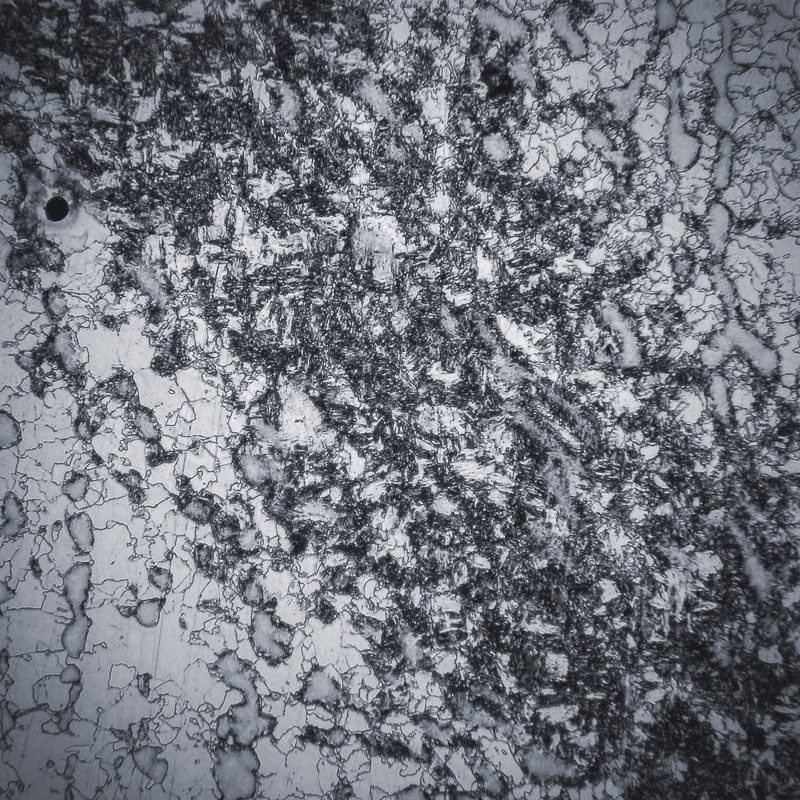

Metallographic

material testing

Metallographic sample preparation

(cutting, imbedding, grinding, polishing, etching)

Light optical microscopy up to 1000 times

Stereomicroscopy to 50 times

Digital Imaging

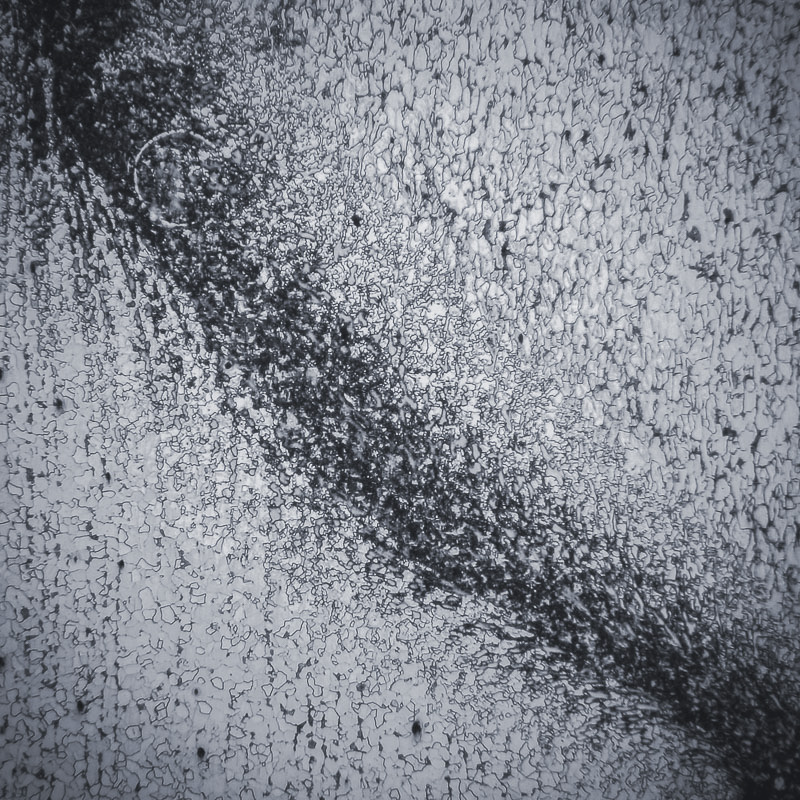

Metallographic

material testing

Metallographic sample preparation

(cutting, imbedding, grinding, polishing, etching)

Light optical microscopy up to 1000 times

Stereomicroscopy to 50 times

Digital Imaging

Mechanical

material testing

Hardness 0.1 to 1 HV

Universal testing machine with digital recording up to 200 kN for:

– tensile test

– load test

– bending test

– push-out test

Hydraulic press up to 400 kN

Heat treatment

(hardening furnace: 1350°C and annealing furnace: 650°C)

Torque testing up to 2000 Nm

Pressure test up to 1000 bar

Push-out and tensile tests of welded parts

Mechanical

material testing

Hardness 0.1 to 1 HV

Universal testing machine with digital recording up to 200 kN for:

– tensile test

– load test

– bending test

– push-out test

Hydraulic press up to 400 kN

Heat treatment

(hardening furnace: 1350°C and annealing furnace: 650°C)

Torque testing up to 2000 Nm

Push-out and tensile tests of welded parts

Exact part measurement

In order to meet the constantly increasing demands on quality, high-precision measuring equipment is available. This enables us to measure the components immediately after welding and make corrections to the process if necessary. In this way, the requirements are reached quickly and efficiently.

Calibrated measuring tools for measuring tolerances for concentricity, parallelism

Image-guided 3D coordinate measuring system

Research

cooperation

We work with regional and national universities for further material, microscopic, technological and scientific studies. We therefore offer you a very wide range of tests.

Ruhr Universität Bochum Lehrstuhl Werkstofftechnik

Internet: https://www.ruhr-uni-bochum.de

Brandenburgische Technische Universität Fachgebiet Fertigungstechnik

Internet: http://https://www.b-tu.de/

Technische Universität Chemnitz Institut für Füge- und Montagetechnik

Internet: http://ifmt.tu-chemnitz.de