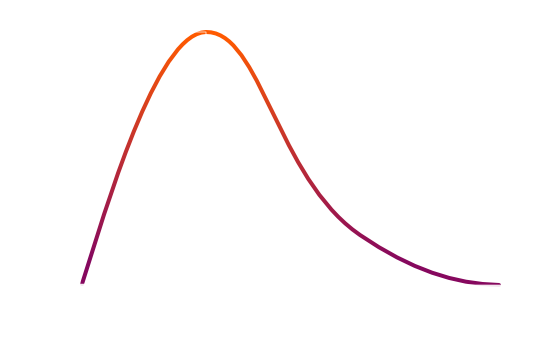

CD welding is characterized by its fast current rise, a very short welding time

10 ms and very high weld currents up to 1000 kA.

This has a number of advantages:

CD welding is characterized by its fast current rise, a very short welding time

10 ms and very high weld currents up to 1000 kA.

This has a number of advantages:

Low mains power consumption

short cycle times

shortest welding times

high precision

High profitability

high energy density

excellent reproducibility

GLAMAtronic

welding technology

CD-welding with a high-current pulse is generated via a transformed capacitor discharge and belongs to the group of resistance welding and in this case to the subgroup of the conductive pressure welding.

The main advantage of the CD-welding, compared to conventional projection welding, is based in a significantly lower mains power.

The high electrical energy required for welding is not taken directly from the mains, but directly discharged from a capacitor bank. The CD-welding basically represents an easy-to-use method with excellent reproducibility and precision, which in addition is characterized by a high operating efficiency.

General

structure

The actual welding time is 10 milliseconds. Due to this extremely short welding time, the welding energy is focused directly on the welding zone. The welded work pieces are taken, compared to the conventional resistance welding, cold from the machine and are almost without distortion due to the low energy input.

Due to the technology used and the short welding time, the CD-welding is a very suitable method with a high current pulse especially for mass production.

Machine

parameters

The CD-welding using a high-current pulse is characterized by two parameters. These are the welding force and welding energy, which always correlate with each other. The welding parameters are adjusted to the part to be welded and set accordingly. This is mainly dependent by the volume of the material that has to be welded. The material volume results from the weld length and width, as well as the setting way. The machine technology and quality monitoring system of GLAMAtronic allow a high and consistent weld quality, as all relevant parameters are monitored.

Joining

technology

The weld geometry at CD-welding is usually carried out with one projection diameter, or some single projections.

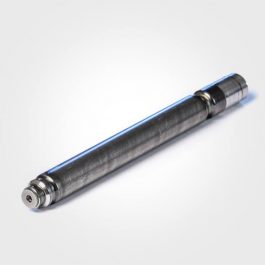

CD-press fit welding

For rotationally symmetric parts

to use of the GLAMAtronic patented press fit welding is very suitable.

learn more

Measurement

and Monitoring

A weld is only triggered when the setting parameters welding force and welding energy are within the allowed tolerances. Before welding, a part check is usually carried out with a low pre force, which checks if the height dimension are within the acceptable values.

During welding, the welding parameters are a welding current and a setting way by which the welded parts to towards each other during joining. With constant welding parameters and constant part geometry, the welding current and the setting way are almost constant. This results in a constant welding quality, which is monitored by the quality monitoring system GKS-Q.

Typical

components

CD welding is usually used for mass produced components e.g. from the automotive industry and their suppliers. Typical parts are airbag components, pump housings, transmission, shock absorber, sintered metal and filter parts. But also components of the heating industry, the electrical industry, the household appliance industry and comparable are very common.