geometry

geometry

Simple

Simple

GLAMAtronic patented press fit welding

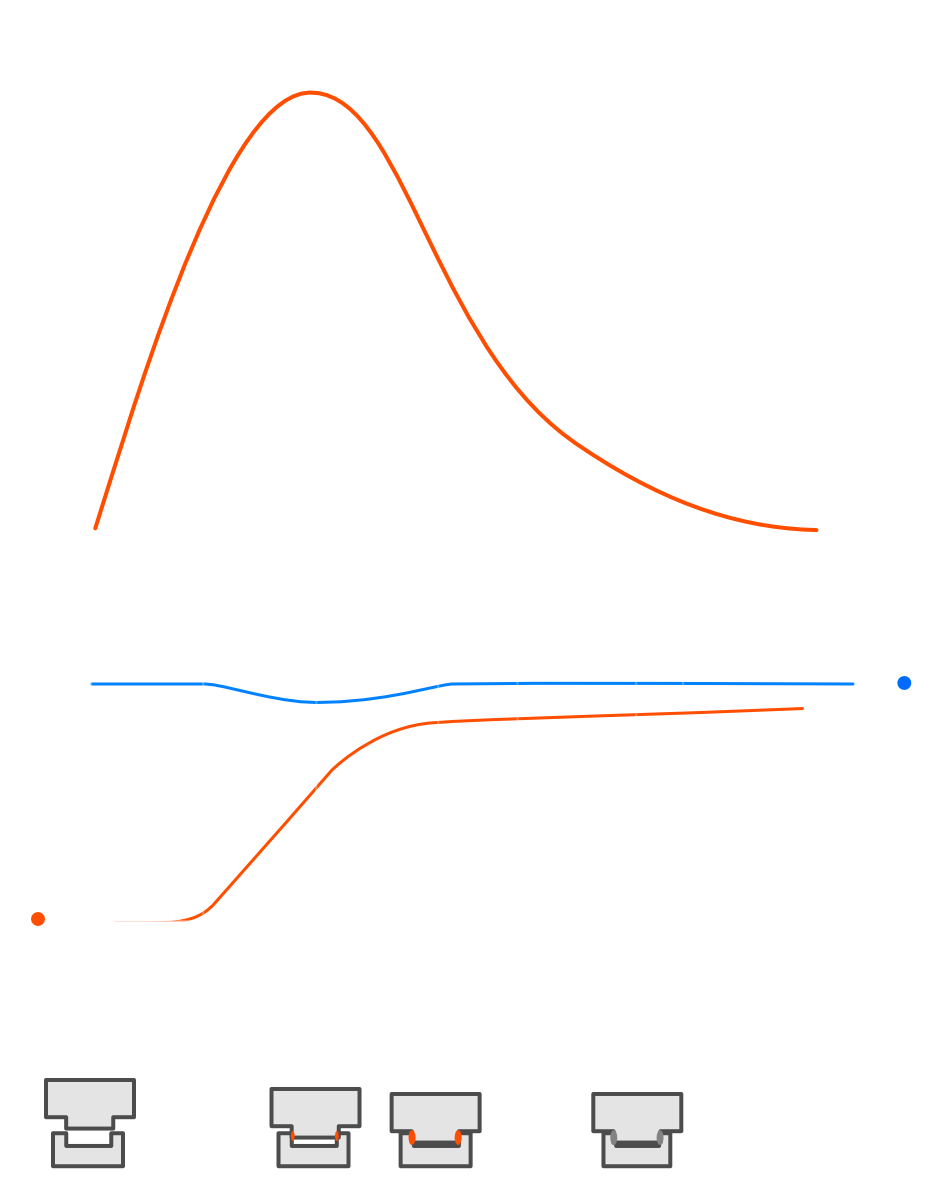

For rotationally symmetric parts an increasingly use of the patented press fit welding can be seen. The technical system requirements and the welding process do not differ from CD-welding with a welding projection. Rather, the advantage is to be found in a much simpler weld and tool design.

The parts need to be designed with a slightly overlap. If one part has a machined phase, the parts show a self-centering behavior once the pre-load is applied. During the discharge of the electrical energy the joining procedure is the same as seen by CD-welding with a weld projection. The joining is formed at the lateral surface of the parts and can reach a length of up to 3 mm.

For CD welding it is important that the machine technology enables a fast follow up of the electrodes. This is achieved through the design of the follow up unit, whereby a sufficient spring travel with minimal force drop must be ensured. Otherwise there may be insufficient welding with reduced weld quality.

The following drawing shows two components before and after press fit welding. The metallographic picture shows a vertical joint zone which results at press fir welding.

For further questions on CD-welding using a weld projection or the CD-press fit welding please contact our development department. They will advise you on design issues and the advantages and disadvantages of each method.

Advantages

of the technology

Vertical weld orientation

Sintered parts also possible

Weld length of up to 3 mm