We automate your work and manufacturing processes and thereby increase your

profitability in the overall process.

We automate your work and manufacturing processes and thereby increase your profitability in the overall process.

Our delivery scope

CD- welding machines

AC and MFDC welding machines

Electrical

controls

GKS-Q

quality monitoring

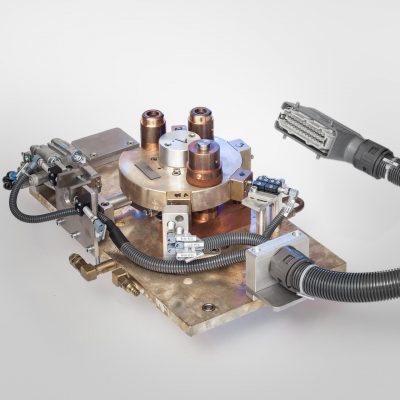

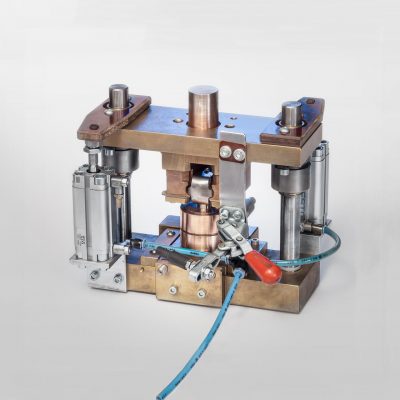

Welding tooling

and fixtures

Automation

solution

Our standard welding machines have an energy range from 4 to 240 kJoules. Parts are handled in customized welding tools. We are set up to build customized welding machines in close contact with the customer.

Our delivery scope

CD- welding machines

AC and MFDC welding machines

Electrical

controls

GKS-Q

quality monitoring

Welding tooling

and fixtures

Automation

solution

Our standard welding machines

have an energy range from 4 to 240 kJoules.

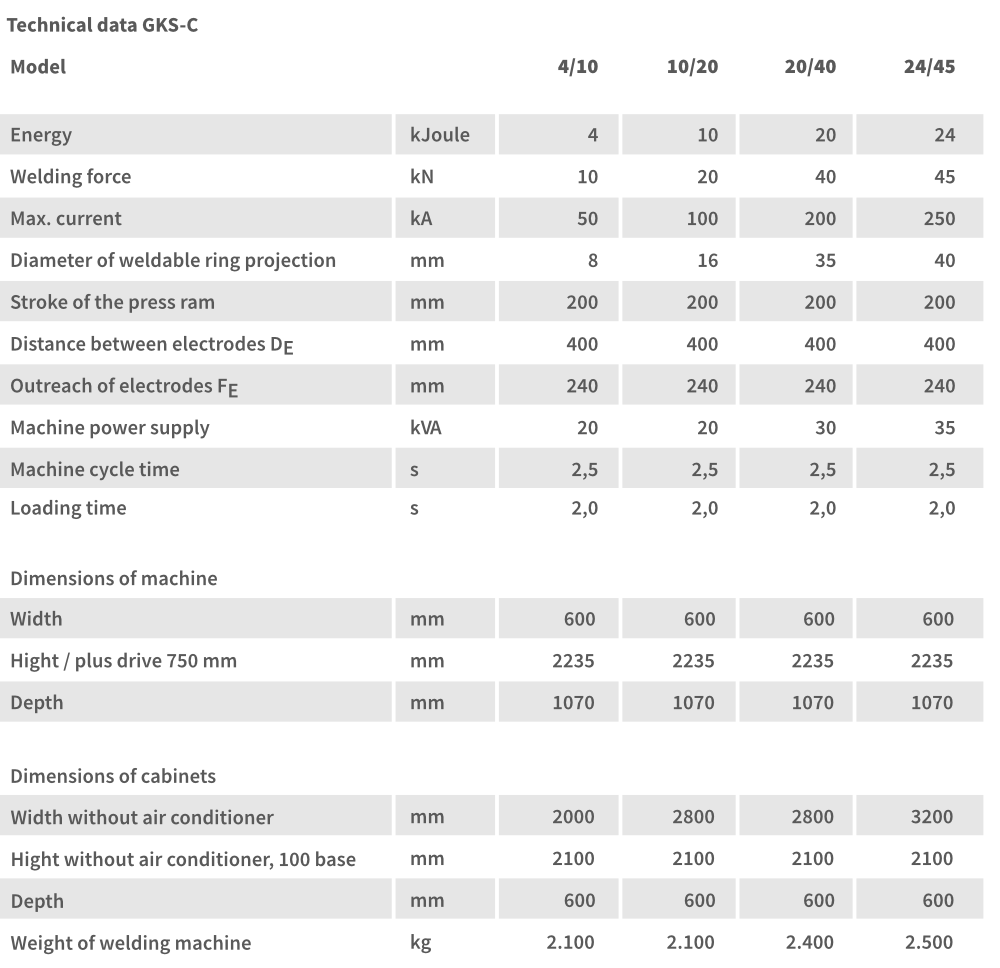

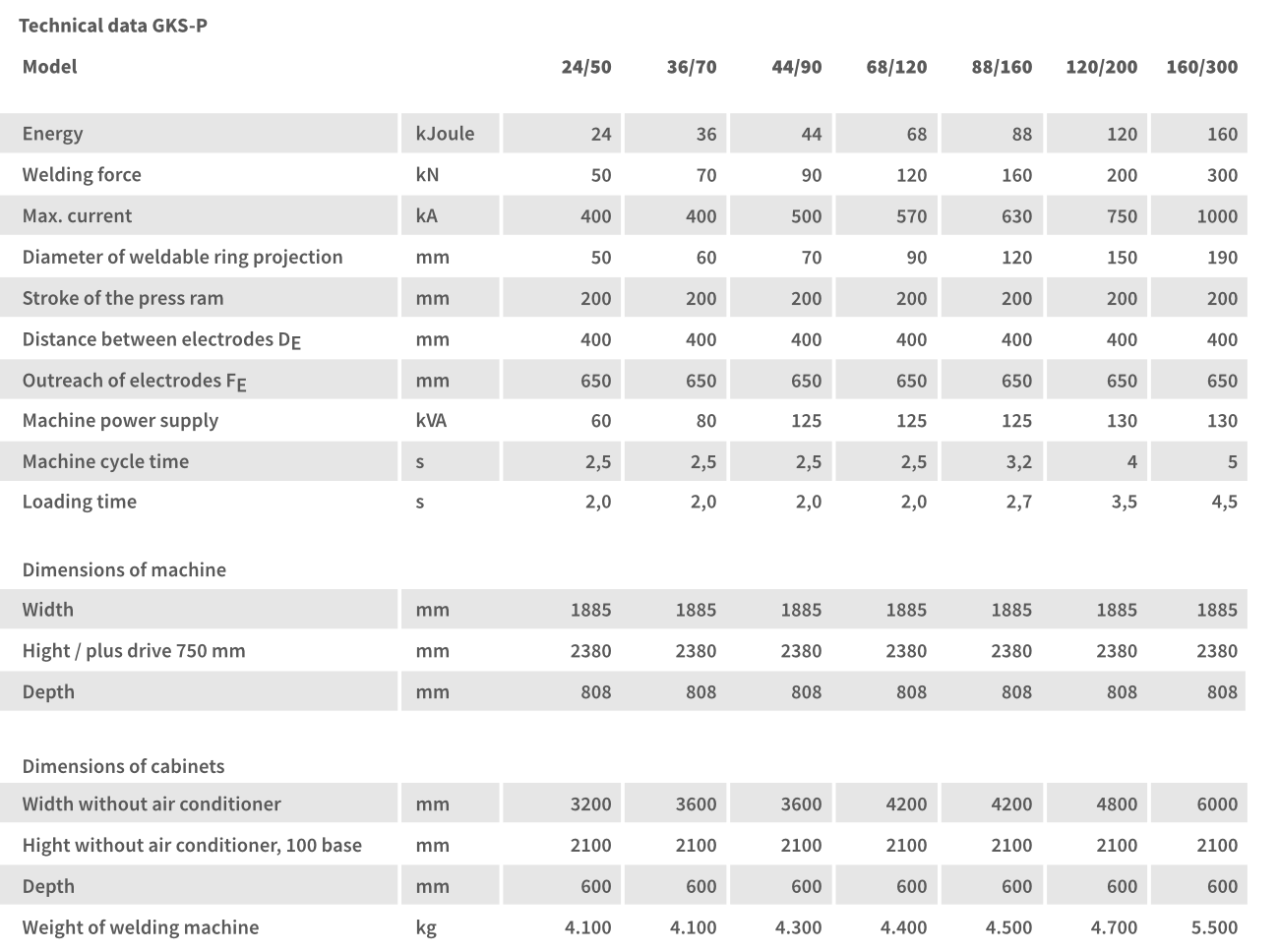

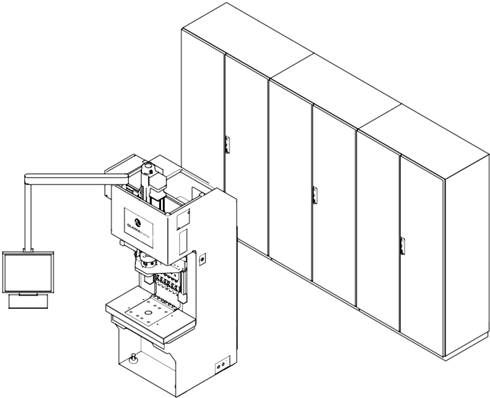

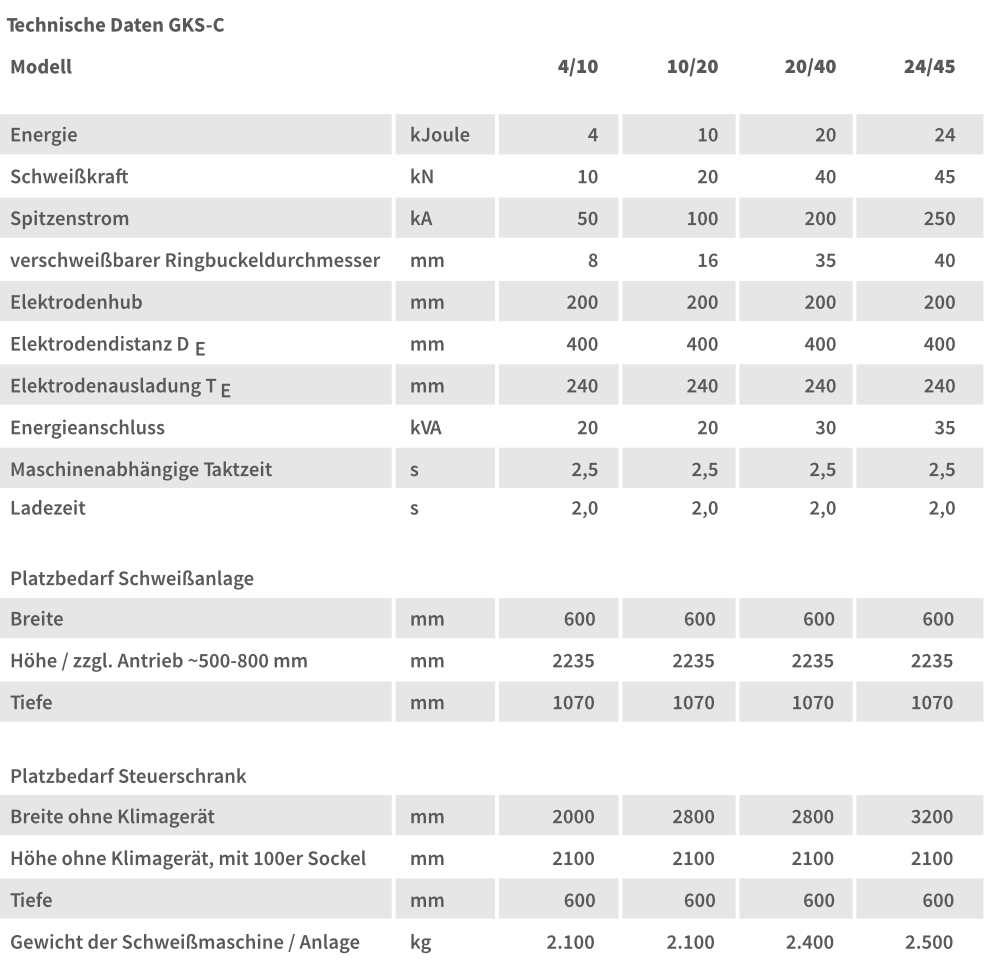

C-frame

welding machines

for the energy range of

4 – 24 kJoule

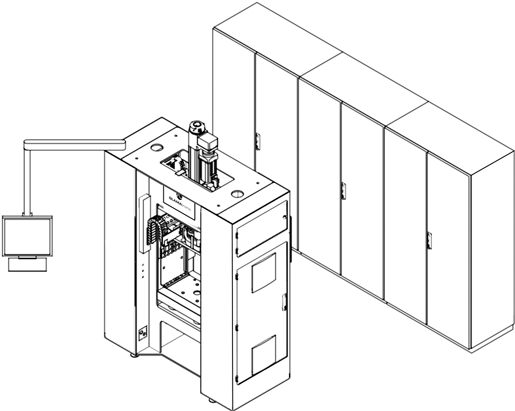

Portal frame

welding machines

for the energy range of

24 – 160 kJoule

TRIPOD frame

welding machines

for the energy range of

160 – 240 kJoule

Schweißanlagen in C-Gestellausführung

für den Energiebereich

4 – 24 kJoule

Schweißanlagen in Portal-Gestellausführung

für den Energiebereich

24 – 160 kJoule

Average

cycle time

1-3

seconds

Total

welding time

<10

milliseconds

Maximum

welding current

1000

kA

OUR

SYSTEM TECHNOLOGY

The selection of the welding machine depends on the conditions of the parts to be welded. The weld geometry, e.g. the number of welding projection or the diameter of the projection. We are set up to build customized welding machines in close contact with the customer.

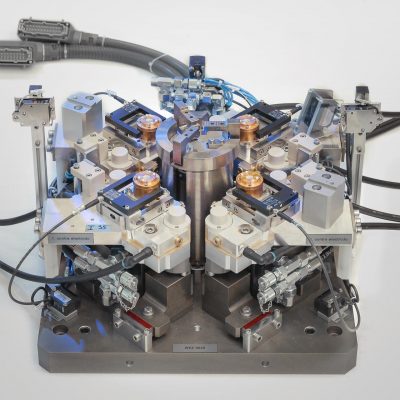

Parts are handled in customized welding tools.

PROCESS INTEGRATION

INDUSTRY 4.0

If required, an automatic interface can be integrated into GLAMAtronic welding machines. This is used to communicate with a higher-level system, through which the welding parameters can be called up, process data sent and external monitoring made possible.

Our GKS‑Q quality monitoring system collects all the relevant data from the welding process, evaluates them and offers you a clear display and analysis options.

Portal- welding machine

GKS-PB 68/120-Q-A

Fully automated process for welding gear parts including part feeding, CD welding, demagnetization and process monitoring.

Customized welding machine

GKS‑S 35/43-Q

Welding common rail applications with double welding tool design in partially automated machine

concept.

C-frame welding machine

GKS-C 48/60-Q-S-Multipuls

Semi-automated welding process for joining high-strength components for seat applications