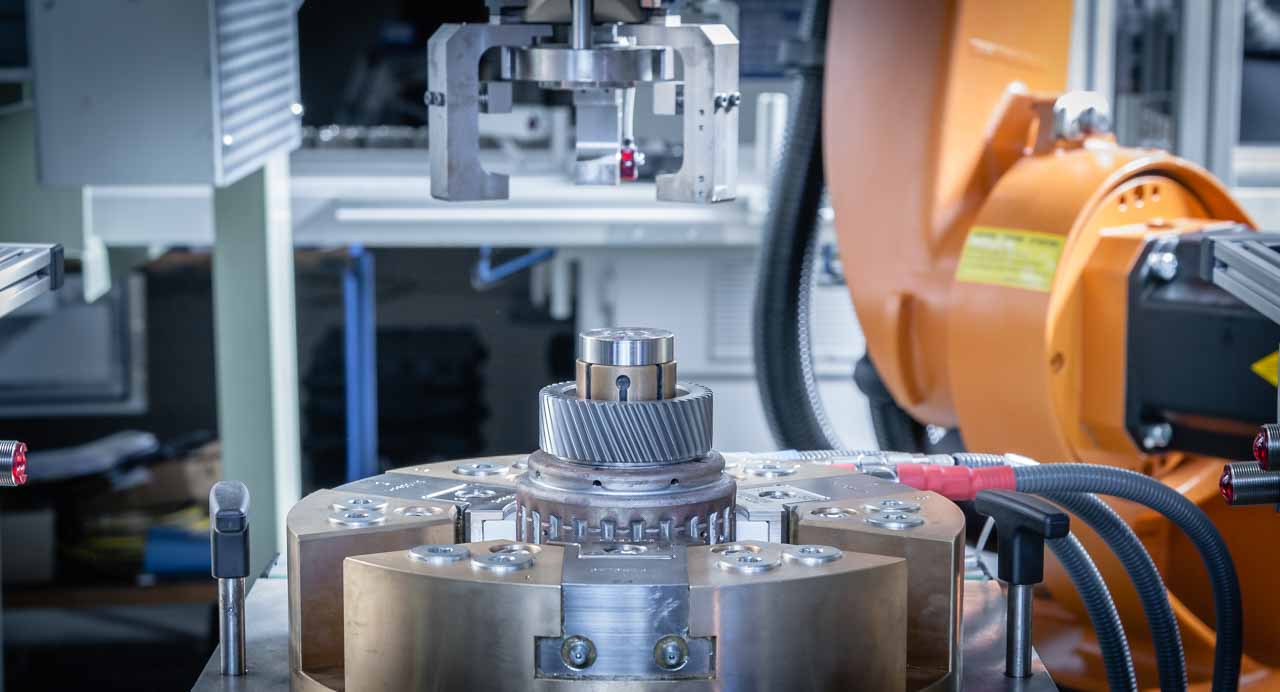

GLAMAtronic builds resistance welding machines with the highest demands on precision and tolerances in order to manufacture components with the highest quality and reproducibility.

GLAMAtronic builds resistance welding machines with the highest demands on precision and tolerances in order to manufacture components with the highest quality and reproducibility.

From the manual machine to the automated overall solution – everything from a single source.and

GLAMAtronic

CD-Welding

Capacitor discharge welding is a variant of projection welding that is interesting in several ways. It is basically an easy-to-use process with excellent reproducibility and precision.

Components with high-strength materials or flexible material combinations, e.g. Carbon-containing steels or coated components require optimal solutions in terms of connection technology.

Advantages

of the process

• Low mains power consumption

• High profitability

• short cycle times

• high energy density

• shortest welding times

• excellent reproducibility

• high precision

Our range of delivery

AC welding machines

MFDC Medium frequency welding machines

Welding tools & Fixtures – design and assembly

Automation solutions

Training & maintenance service

Process development

Contract welding on behalf of customers

“Our specialized welding technology ensures your future success!”

Quality monitoring system

GKS-Q

The welding process is checked online by our integrated quality control. The essential parameters for each welded part are monitored and documented.

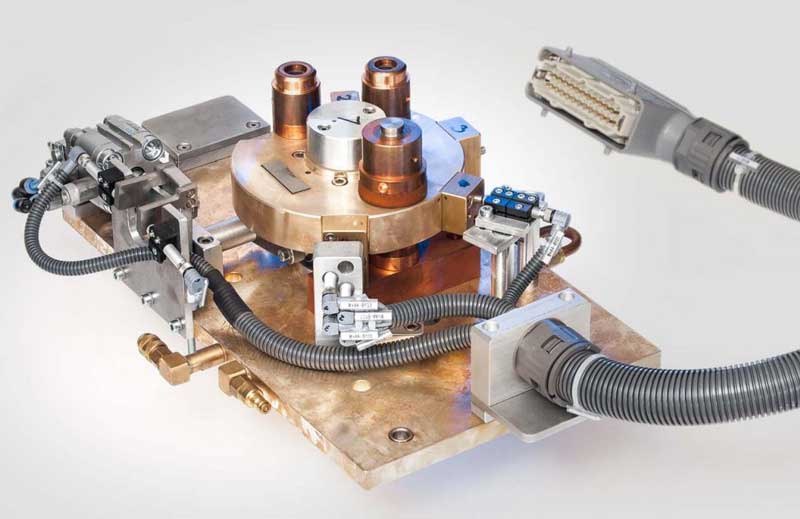

Welding tools & Fixtures

GKS Tools

With customized welding tools and fixtures, we offer you our complete solutions from a single source.

Typical components

GKS-Welding

Mass produced components from the automotive industry and their suppliers such as airbag components, pump housings, transmission, shock absorber, sintered metal and filter parts.

Valeo

AG

Magna

International

Rexroth

Bosch Group

Daimler

AG

PP

Poppe + Potthoff

FAW

Group

VW

Volkswagen AG

BMW

AG

TRW

KFZ Ausrüstung GmbH

ZF

Friedrichshafen AG

ISRI

Isringhausen

your partner for welding

With financial support from the State of North Rhine-Westphalia and the European Social Fund