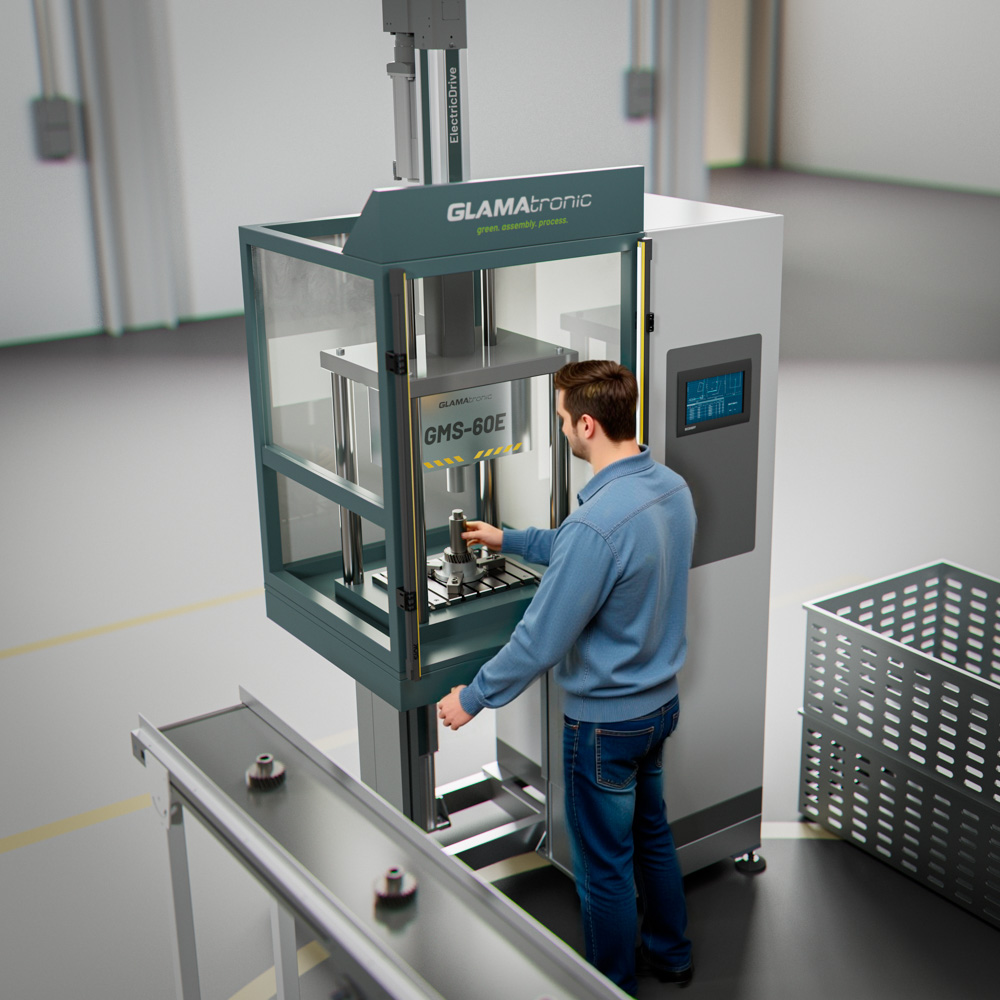

Electric Assembly Station GMS-60E

With an electric drive instead of hydraulics, the GMS-60E reduces installation and maintenance effort, lowers energy consumption and saves floor space – without compromising precision or process quality.

Assembly,

redefined

The GLAMAtronic GMS-60E represents a new generation of electrically driven assembly stations in the 60 kN to 500 kN force range. It combines precise force and position control with a fully integrated Beckhoff control system, providing the foundation for automated assembly processes with maximum repeatability. Integrated quality monitoring continuously tracks all relevant assembly parameters, ensuring documented process reliability.

Key benefits at a glance:

• 60 kN electric drive force – precise, low-maintenance and energy-efficient

• 1–200 mm/s stroke speed – flexible for a wide range of assembly tasks

• Force and position control – for highest precision and repeatable assembly quality

• Prepared for robotics and line integration – scalable for automated production

• Integrated quality monitoring with OK/NOK indication

Key benefits at a glance:

• 60 kN electric drive force – precise, low-maintenance and energy-efficient

• 1–200 mm/s stroke speed – flexible for a wide range of assembly tasks

• Force and position control – for highest precision and repeatable assembly quality

• Prepared for robotics and line integration – scalable for automated production

• Integrated quality monitoring with OK/NOK indication

Flexibility that scales

with your production

Thanks to its modular design and open interfaces (EtherCAT, OPC UA, MQTT), the station can be seamlessly integrated into existing production lines as well as new automation and robotics systems.

The GMS-60E can be configured for different operating modes:

Manual Operation

for small batch sizes and complex single-part assembly

Semi Automatic Operation

Operator-assisted process, e.g. with feeding or removal unit or cobot support.

Automatic Operation

Fully automated version, e.g. with robot integration.

Linked Assembly Line

for multi-part assembly with automatic process control

Technical

data & variants

The GMS-60E is designed for repeatable assembly processes. All relevant parameters are adjustable – from stroke speed to working height.

Technical key data:

• Working force: 60 kN electric drive / up to 500 kN depending on configuration

• Stroke speed: 1–200 mm/s

• Table height: 900 mm ± 250 mm

• Footprint: 1,300 × 800 mm

• Control system: Beckhoff (prepared for automation & robotics integration)

• HMI: 10″ touchscreen with a clearly structured user interface

• Quality functions: force and position control, OK/NOK indication, process documentation

Process integration &

quality management

The integrated quality management system monitors all force, distance and time parameters for every single work step. Any deviations are detected, visualized and documented immediately – ensuring 100% traceability and precise quality monitoring throughout the entire assembly process.

The Beckhoff control system enables full integration into higher-level control systems, robotics and handling systems, as well as databases for process documentation. Via standardized interfaces, process data can be captured, analyzed and archived in real time – a key step toward automated assembly and Industry 4.0 manufacturing.

Cost-effectiveness

through efficiency

The GMS-60E replaces energy-intensive pneumatic systems with an electric direct drive – permanently reducing operating costs, maintenance time and energy consumption.

Thanks to its compact design (1,300 × 800 mm footprint) and height-adjustable worktable, the station can be optimally integrated into existing production environments without requiring additional floor space.

Benefits at a glance:

• Up to 75% lower energy consumption compared to hydraulic systems

• No hydraulic oil – no leaks, no oil changes

• Lower maintenance costs, longer service life

• Consistent quality through precise force and position control

• Ideal for cleanrooms and clean production environments

• Modular retrofit capability

Application examples

Gear with shaft

Precise joining and testing for highly loaded gear–shaft connections.

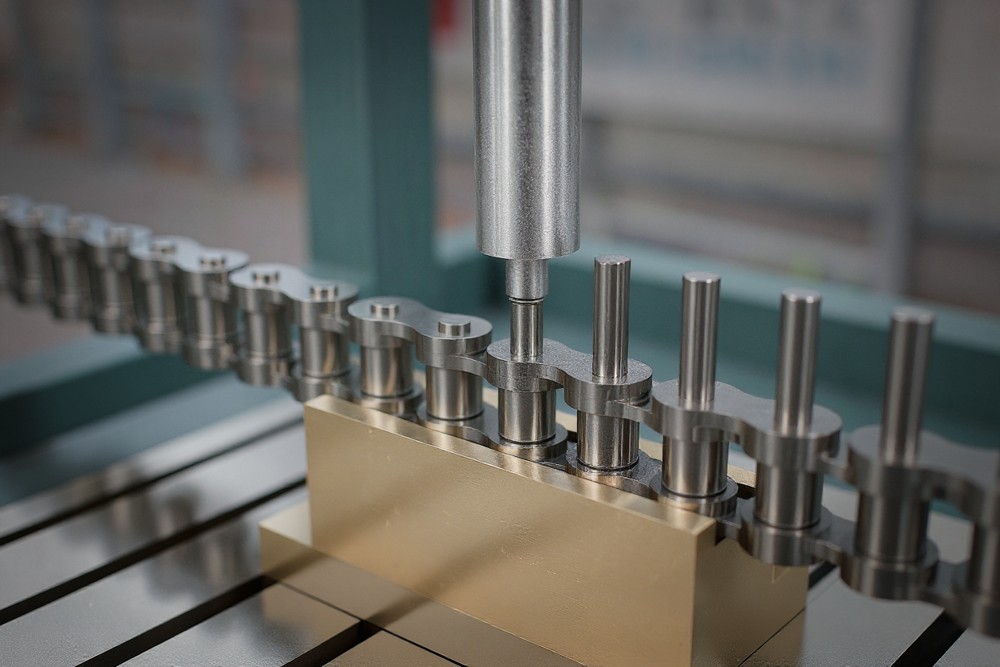

Chain

Series-capable joining and testing of multiple chain links with consistent force distribution.

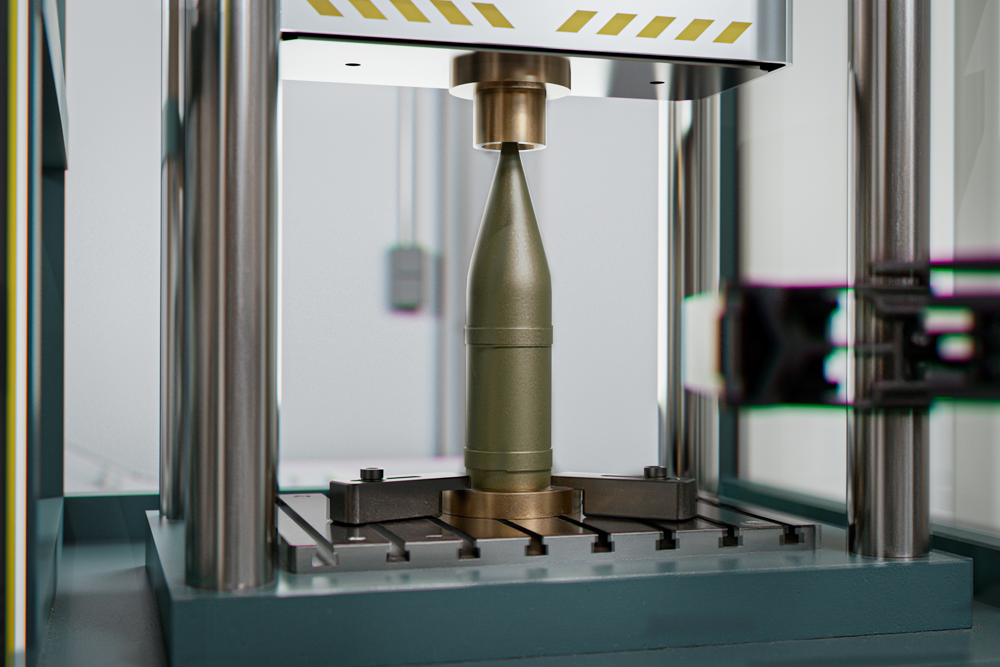

Projectile

High-precision joining and testing of safety-relevant, rotationally symmetrical components.

Additional

technical applications

Tension/compression test fixture & press-out station up to 500 kN

Präzise Bauteilprüfungen mit der elektrischen Montagestation GMS-60E

Relation to the assembly station

The electric assembly station GMS-60E can, with only minor modifications, also be used as a high-performance tension/compression test fixture or press-out station. This allows mechanical components to be tested under realistic conditions with high accuracy and repeatability – at test loads of up to 500 kN.

Applications

Thanks to its robust design, precise measurement technology and flexibly configurable clamping, the press-out station is suitable for a wide range of tasks – from material testing and functional and quality inspections through to development and endurance testing.

Benefits / features

The intuitive control system, optional data recording and modular expandability make the GMS-60E the ideal solution for testing tasks in research, development and series production. The result: precise test results, maximum repeatability and a durable, low-maintenance technology – made in Germany.

Frequently asked questions

about the GLAMAtronic assembly system

How does the GMS-60E differ from conventional assembly stations?

It combines a precise electric axis with integrated force/position control and a Beckhoff control system – enabling repeatable results while keeping energy consumption low.

Can the GMS-60E be integrated into existing automation systems?

Yes. The GMS-60E can be easily integrated into existing plant control systems via standardized interfaces (e.g. fieldbus/Industrial Ethernet). Signals for start, release, good/bad parts as well as process data can be transferred directly to your higher-level system. This makes the station suitable both for new installations and for retrofitting into existing production lines.

Which quality functions are integrated?

The system monitors every joining process using force and displacement curves. Limit values and tolerance windows can be freely parameterized, allowing each assembly operation to be evaluated automatically. Deviations are detected immediately, parts can be rejected, and process data can be stored for documentation – ideal for fully traceable quality assurance.

Which variants are available?

The GMS-60E is available in different configurations, for example:

-

Different strokes and force ranges, matched to your specific components

-

Optionally as a stand-alone station or for integration into transfer or rotary indexing tables

-

Optional extensions such as workpiece carrier handling, safety enclosure, light curtain or additional measuring stations

This allows the station to be tailored exactly to your process.

For which applications is the system particularly well suited?

Typical applications include:

-

Joining, pressing and press-fitting of components

-

Assembly steps with a defined force/displacement profile

-

Functional and leak tests in combination with assembly

-

Applications where repeatability, quality assurance and energy efficiency are more important than pure cycle time

In short: wherever reproducible results and documented processes are required.

How economical is the use of the GMS-60E compared to pneumatic systems?

Electric drives are significantly more energy-efficient than conventional pneumatic solutions, because only the energy actually required is used.

In addition, the integrated process monitoring and high repeatability reduce scrap and rework. Lower maintenance effort (no valve manifolds, fewer wear parts) and improved utilization thanks to flexible parameterization ultimately result in lower unit costs – especially for medium and high production volumes.

We look forward

to hearing from you.

ould you like to know how the GLAMAtronic assembly system can be integrated into your production environment?

Whether you need general information or individual consulting – feel free to contact us.

Contact:

Dr.-Ing. Philipp Schütte

Phone:+49 2043 4835-110